My Roland hiring story:

I was about 22, quite broke and at the time programming my own Apple II graphic adventure game.

I would temp at different companies in the area using a temp agency.

Of those, I had one job where I assembled wiring harnesses in a room filled with only women.

Another was at ITT Cannon, a famous maker of connectors.

It was there I stayed the longest.

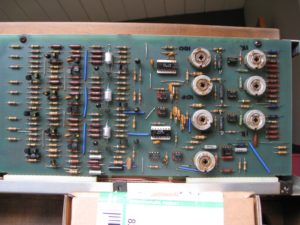

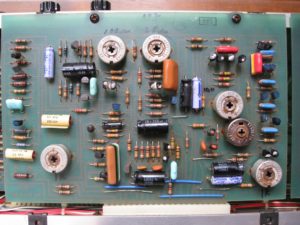

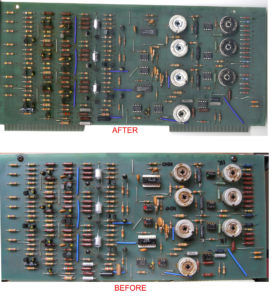

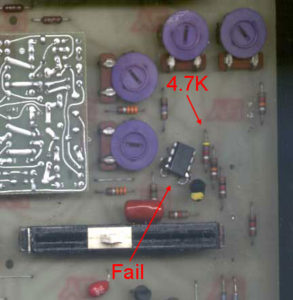

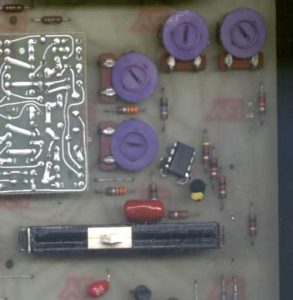

I was given a room with a bench and some parts and a much older gentleman would give me a schematic and tell me to make the board.

These boards were all done using wirewrap methods, not printed circuits or soldered.

As it turns out, I was making devices to shut down or monitor huge machines when they got jammed, out of parts or for whatever reason, wrong.

It was the first time I used an IR thermometer.

One you just point at something and get a temperature.

My boss was a somewhat scattered brain, but highly focus-able man named Eduardo Miranda.

In the last 30-60 mins of the day, he’d teach me electronic theory on a blackboard.

I never expected that, but it was nice to be in a class of one and able to ask questions directly. He helped mentor me beyond what I had been learning since I was very young.

ITT was interesting.

It was a secure company with badges required and it was filled with dimly lit warehouses of oily and steamy machines.

Going into the warehouses became a real drag.

While I got to sit by myself and make circuits, I also had to install and calibrate them.

I also had to work on antique computer called a Data General Nova where it had rows of boards about a foot square. Half were originals, half were to control all the machines and again, wirewrapped.

Since the environment was oily and steamy and these boards were filled with thousands of connections, working on this beast became a whack-a-mole type duty.

I was pretty fed up, jobs were easy to get and I left.

Only afterward, did I learn that they wanted to hire me full-time and at a substantial raise with benefits.

My next job was soldering boards.

Again, all women around me.

That was an ok job, but they listened to the oldies radio stations and that meant hearing 1950’s music all day.

Whatever, it was a cake job.

I also was traveling to every musical instrument repair shop in LA.

I visited them all and all turned me down.

One place was called Hi-Tech Electronics. It was owned by JL Cooper, a prominent engineer. But he didn’t fix synths, he had others man the shop.

One of my neighbors at the time was also Michael Basich, a one-time member of Oingo Boingo.

He was already a tech at Hi-Tech.

But the guy I met was named Tim.

Tim had an attitude.

He had an open JP8 in front of him and with a smirk asked if I’d ever worked on anything so complex before, basically laughing at me for his assumed answer.

I told him yes, I had. He brushed me off.

Another was a guy on Sunset blvd in guitar row. (if you’re from Hollywood, you know the area.)

He had an upstairs shop that was tiny, but he secured the repairs from the Guitar Center across the street and had gear up to his eyeballs.

I don’t know if he was on drugs or not, but he couldn’t look me in the eye, was very jittery and gave me the spooks.

Finally he said, if you can fix that, you can have a job.

What he pointed to was a Teac Portastudio.

It seemed that when you put it in a certain mode, two of the meter lights went out.

I told him that was normal. It was in two track playback mode and even showed him it in the owners manual right next to it.

Insulted, he got huffy and I didn’t get that job either.

I also asked Paul Morte who had secured all the repair work for Yamaha.

He basically blew me off too, but admit I only spoke to him on the phone and should have driven down to his place.

Around this time one nite, I was up late programming my Apple.

It was about 10:30PM and the phone rang.

It was my friend Bruce in a semi-panic.

The problem was that he had this friend named Forrest who worked at a newly formed division of Roland called Roland DG, they were about to start exhibiting at Comdex and had no video demo for their new line of monitors.

They were about to display video monitors with no video.

Not good.

Bruce asked if I could make a self-demoing slide show of various pics on an Apple II and get it to them at Comdex the next day.

So I did just that.

I thought, wow… well, yeah I can do this, but how do I get there?

I had no money to fly to Las Vegas.

I begged my mom.

She loaned the money. It was about $80 at the time.

I made a slide show that held about 30 nice display pics, repeated automatically and via a 6502 machine-language routine, I made each photo display the name “Roland” in the corner as an overlay.

It worked fine though I actually made a mistake- I used Roland’s Musical Logo; Roland DG had their own logo, but everyone was still happy.

The next morning I put on my best clothes and flew out to Comdex by myself with only a few dollars in my pocket for lunch, a disk and a return ticket.

By the way, Comdex is huge. It’s covered at the same time in several hotels.

I had to do a lot of walking, but got to the right hotel where Roland had an Apple computer waiting.

The display installation worked well and so went the first showing of Roland DG at Comdex.

As I was leaving, I met Forrest and we began chatting, but his face suddenly went pale.

He said he saw something he’d never seen.

The president of Roland US, Tom Beckman, had excused himself from speaking with some Japanese men and was walking in our direction.

Tom came over to thank me for doing the slide show and asked if he owed me anything.

It was at this point that I knew I had to say something.

I quickly blurted out “Well, I need a job!”

Tom stopped and listened as I explained that I’d already been fixing synths for years, knew digital stuff and could program.

It all came out as one sentence and I felt foolish, but I was nervous and also had a plane to catch soon.

But it was a now or never moment and even Forrest stayed silent as he appeared to witnessing something he’d never seen before.

Tom calmly pulled out a Roland business card with his name on it and wrote down a name on the back: Jimmy Mothersbaugh.

He told me to call Jimmy when I got back in town.

I think I waited until Comdex was over, but called the number and asked for Jimmy.

A man came on the phone and basically said I was hired.

Could I start the following week?

I said goodbye to the ladies of soldering and drove out to Roland on what did turn out to be a new job. They gave me my own tech room, a small tour and introductions to various people.

As it appears, Jimmy was told by Tom to check me out or hire me and Jimmy did just that. I went to the top first and everyone below was intimidated or following orders.

For what it’s worth, Jimmy is actually Jim Mothersbaugh and Devo’s first drummer, brother to the other members of Devo. Through the years at Roland, I’d get to see and hear much of what Devo was doing via Jim.

But that first day, Jim was apprehensive.

I had never given him a resume.

I never filled out a job application.

He told me, “You know if you only last here a short time, it will at least look good on your resume.”

I felt crushed, but knew he didn’t know much about me then either.

I stayed there from late 1984 to early 1988.

For a long time, I was the only authorized service center for Roland DG monitors and plotters. They had none authorized anywhere else in the US.

All the other techs were very happy about this too.

They wanted to get back to fixing synths and boss pedals and hated the DG line and management.

My record of video monitors repaired in one day is 25.

Most were ok, but all had to be unboxed, checked and reboxed.

Many did need legitimate repairs also.

But I got bored at Roland.

Every year they’d release 60-80 new products and we had to fix them in addition to the old ones. Parts were everywhere and stacked higher than anyone could reach without a ladder.

We were out of space. The file cabinet with service manuals was packed.

We also had to install and tear down the Namm show displays each year, which got progressively bigger in production with stages and huge displays.

The years went on and I felt like I was going nowhere there.

Depressed over a recent girlfriend breakup and wooed by a (so called) friend to work at his company and open my own shop, I left Roland.